UV LED

By using high-output UV-LED, the output is significantly improved compared to traditional products.

Four shapes: point light, ring, strip, and light strip.

Wavelengths include: 365nm, 385nm, 395nm and 405nm

Official website https://www.ccs-inc.co.jp/products/series/353

Compared with the traditional UV series and UV2 series, the new version of UV3 LED has a richer product lineup and higher brightness.

-Four shapes: straight line, ring, bar and dot.

-The product lineup includes wavelengths 365nm, 385nm, 395nm and 405nm.

-Two light directionality options are available: wide light direction for wide-area illumination, and narrow light direction for focused illumination of narrow areas*.

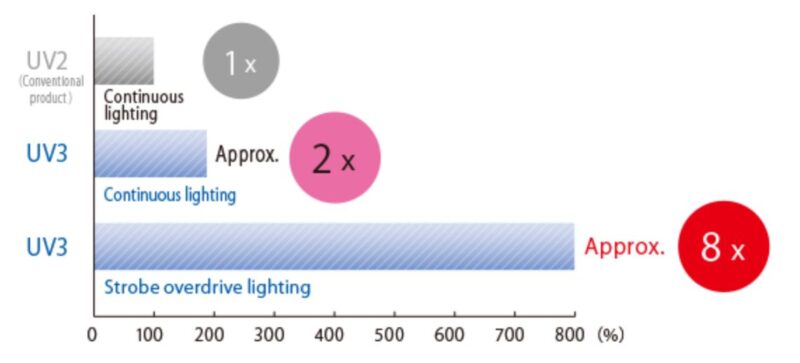

-The output is twice that of the previous UV2 series, and it also supports overspeed to increase inspection speed.

-Used for various inspection purposes such as fluorescence observation, coating inspection, flaw detection, etc.

*Available in wide and narrow types: ring type (LDR2), rod type (LDL) and high output linear type (LNSP-FN)

The picture above shows the comparison between LDR2-60UV3-365-N and LDR2-60UV2-365-N. For LWD100mm, the brightness increase ratio varies by model. (These are reference values, not guaranteed values)

The picture above shows the comparison between LDR2-60UV3-365-N and LDR2-60UV2-365-N. For LWD100mm, the brightness increase ratio varies by model. (These are reference values, not guaranteed values)

UV light source application

■Sealing material detection through excited fluorescence

■Reading invisible codes

■Detection using differences in spectral reflectance

■Detection using differences in scattering rates

Commonly used wavelength bands of UV LED are 365nm, 385nm, 395nm and 405nm

Shooting examples

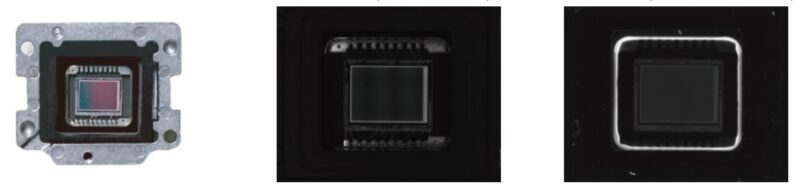

Photograph the bonding area of the sensor substrate

Sensor substrate LED white (LDR2-90-30SW2) LED UV(LDR2-100UV3-365-W)

Difficult to capture bonded areas The fluorescence, can observe the bonded area

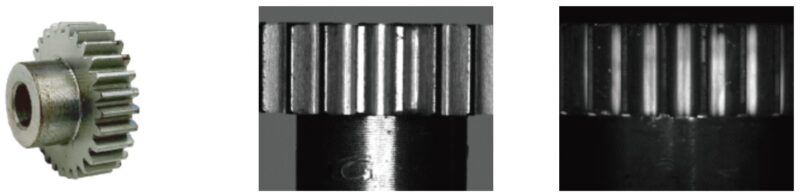

Grease application diagram on gear parts

gear parts LED white lighting(LDR2-90SW2) LED UV lighting(LDL-138X12UV3-365-W)

Difficult to determine lubricant application status on uneven surfaces The lubricant in the dented area can be observed to fluoresce

If you have other customization requirements, please call us.